Superconducting YBa2Cu3O7-x

Synthetic procedure from Colin Greaves, "Structural, Electrical and Magnetic Properties of Perovskite Ceramics," in Inorganic Experiments, edited by J. Derek Woolins, Wiley-VCH, 1994, pages 265-270 (ISBN 3527305106).

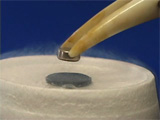

The magnetic flux of a magnet will not penetrate a superconducting material, enabling a magnet to be levitated on a superconducting material. In this experiment a pellet of YBa2Cu3Ox is prepared and cooled to its superconducting state in liquid nitrogen. See A. B. Ellis, " Superconductors: Better levitation through chemistry," J. Chem. Educ., 64(10), 836-841 (1987).

| Procedure | Wear eye protection |

Thermal gloves recommended |

Dry reagents (Y2O3, CuO, and BaCO3) in an oven at 400°C for several hours. Weigh out a 1:2:3 molar ratio of Y:Ba:Cu (0.3023 g CuO, 0.5000 g BaCO3,and 0.1430 g Y2O3). Grind the materials to mix. Load 1/3 to 1/2 the material in a 13-mm diameter pellet die. Press at 5000 kg in a hydraulic press. Make two or three pellets total. Transfer the pellets to an alumina boat and load into an open quartz tube in a tube furnace. Heat at 930°C for 12 hours.

Cool to 500°C and hold for 1 hour.

Cool to 400°C over 30 minutes.

Remove and/or cool to room temperature

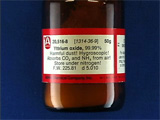

- CuO, cupric oxide, Aldrich 450812, Acros AC40586

- Y2O3, Aldrich 205168

- BaCO3, Aldrich 237108, Fisher B30

- 400°C muffle furnace, crucible

- mortar and pestle

- pellet die and press

- 930°C tube furnace, alumina boat

- small magnet, tweezers, foam cup, liquid nitrogen

Long term exposure to moisture may cause the pellet to crumble. A wax or polymer

coating may help preserve the pellet.

Additional levitation movies

University of Wisconsin Materials Research Science and Engineering Center

Interdisciplinary Education Group | MRSEC on Nanostructured Interfaces

This page created by George Lisensky, Beloit College. Last modified June 16, 2013 .