Heat Treatment Training of NiTi

This procedure was developed by Eric J. Voss. We acknowledge Angela Erickson for designing the sample and helping with the filming.

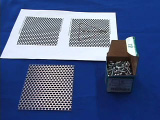

Shape memory alloy wire can be "set" into a new shape by heat treatment while holding the wire in the desired shape. Since SMAs exert substantial forces during this heating, a relatively strong heat resistant jig capable of withstanding forces exerted by the NiTi wire and temperatures up to 600 degrees Celsius must be used. Rather than using a jig produced on expensive tools in sophisticated machine shops, this experiment uses jigs made of an inexpensive perforated aluminum plate and standard nuts and bolts.

| Procedure | Wear eye protection |

Begin by designing your NiTi wire shape on a paper template (Sample jig plate image). This planning stage prevents poor designs and avoids waste of NiTi wire. Once the template is designed, bolts are threaded through the appropriate holes in the base plate and secured with hex nuts. Use string to measure the length of wire needed. Obtain the proper length of NiTi wire. Wrap the wire around the bolts and secure with a second hex nut where needed. Place the jig in a 550 degree Celsius oven for approximately 15 minutes. We have observed softening of the aluminum plates after several cycles of heating, but plate softening is generally not a problem. More than one jig may be heated in the oven at one time. Quench the jig in a cold water bath. Check the response of the SMA wire by straightening the wire and looking for shape recovery after it is immersed in hot (boiling) water. Cycle through the phase transition several times to study repeatablity. Another student-designed sample. The modular nature of these jigs leads to the added advantages of (1) design flexibility (shapes, letters, words, and even three-dimensional objects are possible), (2) unique projects for each student (each student sets wire into his or her own individual shape), and (3) reusability of the jigs (a classroom set of jigs may be cycled through many sections of a laboratory).

Conclusions

- Hand in your template pattern.

- How well did your shape memory wire come back to the designed template pattern? Was your phase transition repeatable? How many times did you cycle it? Is NiTi a "smart material"?

- Why does it matter that the wire is bolted tightly at the ends? Why can't you just tie a knot?

- Could you do this experiment in the oven in your kitchen? Explain why or why not.

- For what application could NiTi with each of the following transition temperatures be used? Be creative. -10°C

30°C

70°C

- The Nitinol wire is available in large quantities (300 ft. of 0.0315 in. alloy type SM-495 (martensite) straight, black oxide finish, from Nitinol Devices and Components or 100 meters of 0.015" Flexinol® 70ºC from Dynalloy).

- The jig is cut to fit the oven from a large aluminum sheet with a hexagonal array of holes (14 gauge aluminum perforated sheet, 36 in. x 40 in., 0.1875 in. hole diameter holes, 9232T191; use round head slotted screw w/ nut, 10-25, 1/2 in., 100/pk., 90232A505, both from McMaster-Carr). Another option is a thinner jig with a square array of holes and smaller diameter nuts and bolts (20 gauge aluminum cane sheet, 3 ft. x 5 ft.., 9344T62; use round head slotted screw w/ nut, 8-32, 1/2 in., 100/pk., 90232A486, both from McMaster-Carr).

Equipment

Developed in collaboration with the

University of Wisconsin Materials Research Science and Engineering Center

Interdisciplinary Education Group | MRSEC on Nanostructured Interfaces

This page created by George Lisensky, Beloit College. Last modified October 2, 2018 .

University of Wisconsin Materials Research Science and Engineering Center

Interdisciplinary Education Group | MRSEC on Nanostructured Interfaces

This page created by George Lisensky, Beloit College. Last modified October 2, 2018 .