Currently, there is much emphasis on the study of magnetic properties of materials. While magnets date back to ancient times, new techniques have made it possible to use magnets in a wide variety of applications, as exemplified by flexible magnets. Perhaps the most common place to encounter flexible magnets is the refrigerator door in the form of flexible sheet refrigerator magnets.

The common flexible sheet refrigerator magnet (RM) has a complex, ingenious magnetic structure. The field lines in the RM are U-shaped; therefore, most of the magnetic field extends from the back of the magnet and very little magnetic field from the front. A RM can essentially be thought of as an array of very small horseshoe magnets. The magnetic field structure therefore comprises a striped pattern of alternating north and south poles on the brown, unprinted side of the RM, with a typical stripe width of 1-2 mm. This unusual magnetic topography can be used for a number of interesting demonstrations and experiments.

Figure 1. (top) Cross-section of a flexible sheet refrigerator magnet and (bottom) its analogy to an array of horseshoe magnets.

RMs are composite materials, typically containing magnetic strontium ferrite, SrFe12O19, particles dispersed in the elastomer Hypalon. Strontium ferrite may be thought of as having the general formula MO-6Fe2O3, where M is a divalent metal cation. The metal M2+ ions (such as Sr2+ or Ba2+) substitute for O2- ions in the close-packed oxygen layers. The Fe3+ ions are arranged throughout this lattice, having oxygen coordination numbers of 4, 5, or 6.

Figure 2. Unit cell model of strontium ferrite built using the Solid State Model Kit.

Figure 3. Chemical structure of the elastomer Hypalon.

During the manufacture of RMs, an array of permanent magnets forms the magnetic stripes as a sheet of ferrite/Hypalon passes by the array. The magnetic fields from the array align the magnetic dipoles of the ferrite particles, resulting in the striped pole pattern. Channeling the magnetic field to the back of the magnet puts the maximum amount of this field to work holding the RM onto a metal surface such as a refrigerator door. The RM poles induce temporary poles of opposite polarity in the refrigerator door, enabling the RM to stick to the door. This site explores RM-based experiments that use these unusual striped structures to demonstrate a number of principles.

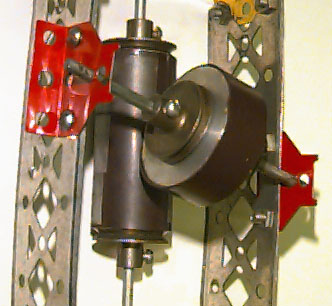

Patrick Doolan has constructed a magnetic worm gear system using refrigerator magnets. The alternating north and south magnetic fields act as the teeth of a gear. The gear system can operate without physical contact between the two gears.

Different materials respond to applied stresses in different ways. How a material

will respond depends on the arrangement of atoms in the material and how these

atoms are bonded together. We have found that flexible sheet refrigerator

magnets can be used to show macroscopically how

salts and metals respond to an applied stress.