MarkIII(k) Planetary Gear

Description:

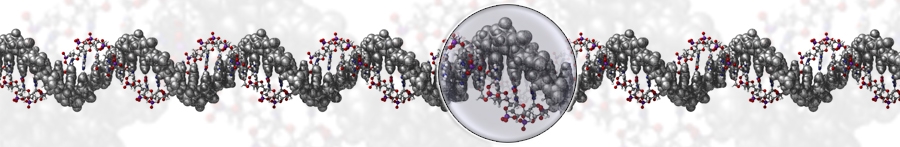

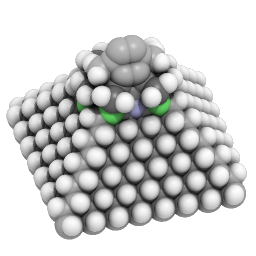

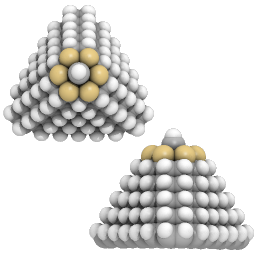

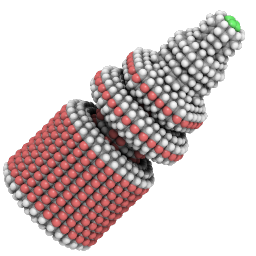

This is the MarkIII(k), a nanoscale planetary gear designed by K. Eric Drexler. A planetary gear couples an input shaft via a sun gear to an output shaft through a set of planet gears (attached to the output shaft by a planet carrier). The planet gears roll between the sun gear and a ring gear on the inner surface of a casing. This animation was rendered with Qutemol by reading PDB files from a NanoEngineer-1 molecular dynamics simulation. A section of the casing atoms have been hidden to expose the internal gearing assembly.

Author:

K. Eric Drexler

Nanorex, Inc.